Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

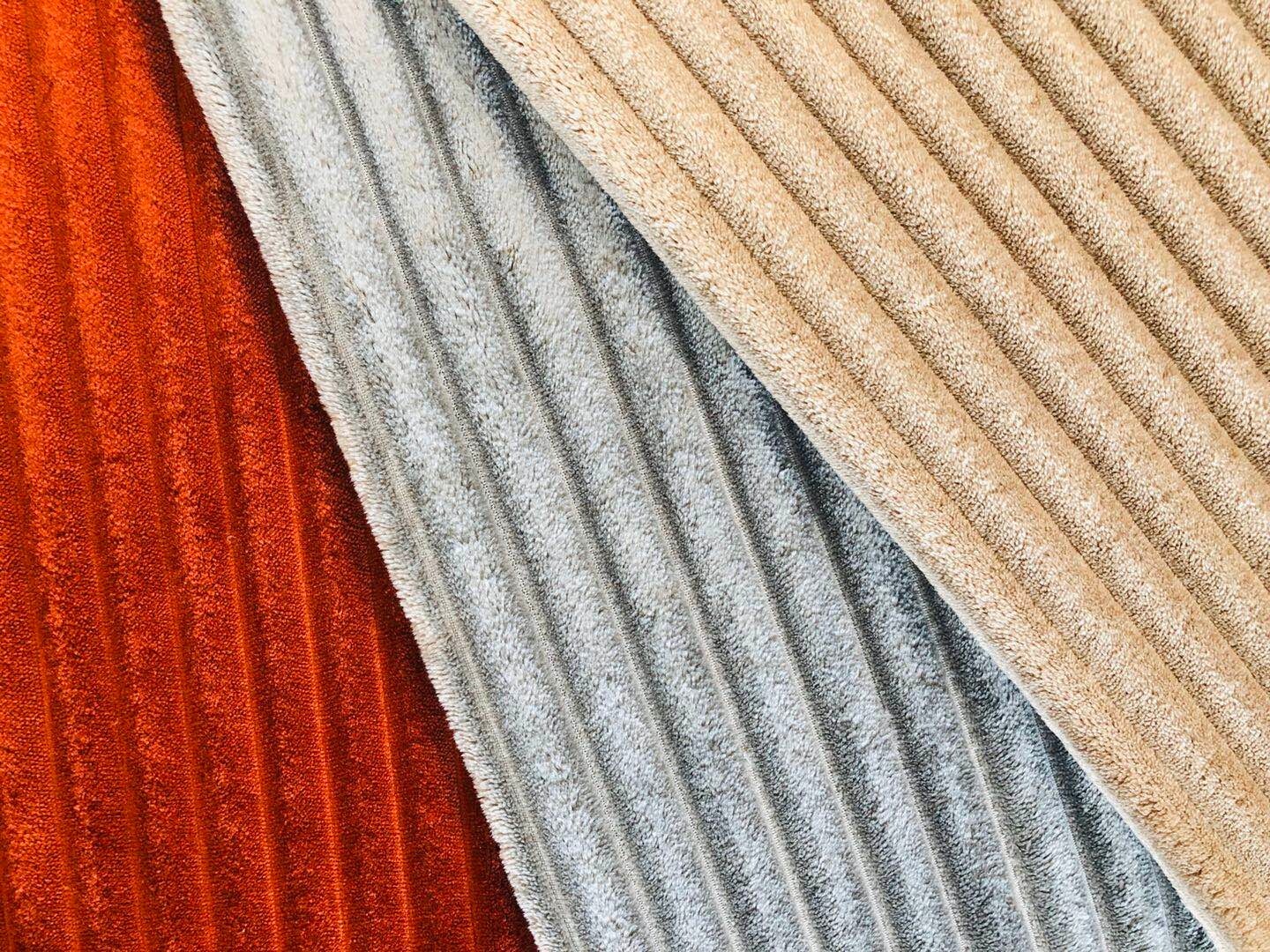

Popcorn Flannel

Flannel fabric is closely related to the ironing process. The two front and rear ironing must be guaranteed, the time cannot be short and the temperature cannot be low so that the quality of the fabrics made by this process can be guaranteed.

Flannel printing and dyeing process

- After the embryonic cloth is woven and broken, it is sent to the printing and dyeing workshop. Whether it is printing or dyeing, the embryonic cloth should be heat-set. The purpose is to pre-shrink the embryonic cloth at high temperatures so that the high elasticity of the raw material can be fixed. Conventional The setting temperature is about 230 degrees (different factories control the temperature differently, generally it will not be lower than 200 degrees), the hair on the wool surface will not be bent during dyeing and finishing, and the hair will feel fluffy and clear.

- To ensure that the backside will not be fluffed in the dye vat (high temperature and high pressure jetting), we will hem the preformed fabric.

- Pre-treatment. In many cases, the finished flannel fabric is very messy and messy after coming out, and it is not clear enough. To improve, we will reduce the amount. However, the cost is a bit high, and the water, electricity, and other time are consumed a lot. Many factories are constantly improving the process. The pressure of the market has caused almost no factories to do this process.

- Dyeing, the dyeing of flannel is not much different from ordinary polyester fabrics, which are all dyed with dispersed dyes at high temperatures.

- After the cylinder is released, we will dehydrate and pull the edges (pull the edges that are sewn together), soften them, and shape the finished product (180 degrees).

- If we make double-sided flannel, we will change it into a raising agent when softening it. Re-shape, let the back and back be brushed, combed, sheared, shaken, and then shaped.

Factors affecting the softness and smoothness of flannel fabrics

At present, in the fleece fabric market, there are great differences in the quality of flannel fabrics. When choosing fabrics, some factories only pay attention to the price difference and do not pay much attention to the difference in fabric quality. High-quality flannel fabrics are thick, silky, and fluffy, while lower-quality flannel fabrics are much inferior in these characteristics.

The main reasons are two points: one is the difference in raw materials, and the other is the difference in printing and dyeing processes. First of all, the raw materials of all polyester flannel fabrics are mainly flat and low elastic fibers of ultra-fine denier fibers. When selecting raw materials, enterprises choose raw materials with low quality and low price and reduce the technological process when adding elastic, resulting in uneven raw materials for weaving flannel, so the quality of the original fabric is often very different.

Secondly, in the process of printing and dyeing, to attract more customers, printing and dyeing enterprises also make a fuss about the price to reduce the technological process and reduce the cost. The smoothness and softness of the flannel are closely related to the ironing process. The two front and rear ironing must be guaranteed, the time cannot be short and the temperature cannot be low so the quality of the fabrics made by this process can be guaranteed.